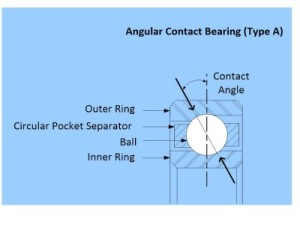

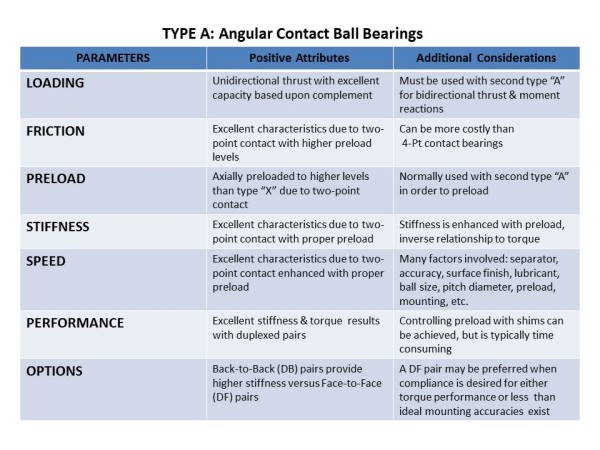

TYPE A: ANGULAR CONTACT BALL BEARING

Type A Angular Contact Ball Bearings are uniquely suited for unidirectional axial loads. Angular Contact Bearings should be mounted with two bearings opposed to one another to react bidirectional and reversing thrust loads, radial loads and moment loads.

Type A bearings contain one ring with a counterbore that is snapped over the ball compliment, separator and second ring. This feature allows type A bearings to be assembled with a full compliment of balls without the use of a loading notch. Typically, type A bearings are assembled with a 2/3rds compliment, which is higher than type R and X’s. The additional balls allow for greater load carrying capacity in the axial and radial directions. A pair of angular contact bearings moment loads capability is also enhanced by the ball compliment and as a function of the distance between the two bearing center-lines.

Type A bearings are an excellent choice when high stiffness is desirable in conjunction with low, consistent torque. A pair of Type A bearings maintain two-point contact under normal load conditions and therefore can be preloaded to a higher degree versus a Type X and maintain desirable torque properties.

Type A bearing are often specified as matched sets when they are mounted adjacent or with equal length spacers. Specifying a matched set alleviates the burden of grinding shims to achieve the desired preload during assembly. Duplexed pairs are offered in back-to-back (DB) or face-to-face (DF) configurations.

Type A bearings are offered with a standard 30 degree contact angle and either a nylon or brass continuous ring, circular pocket separator. Typically Type A bearings are offered in only an open configuration; however, APG offer most angular contact bearings with single or outboard seals or shields.

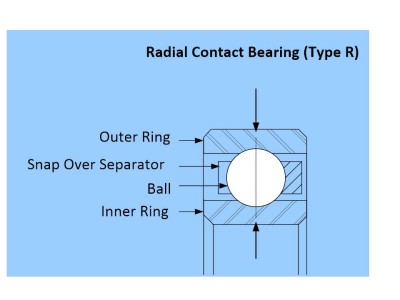

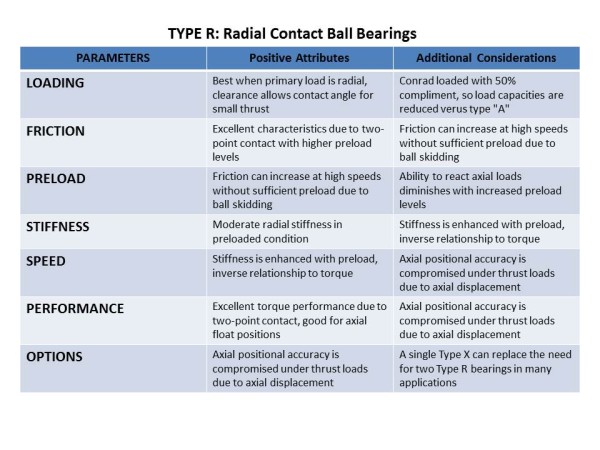

TYPE R: RADIAL CONTACT BALL BEARING

Type R Radial Ball Bearings are deep groove, single row bearings suited for radial loads and small thrust loads. The standard bearings are offered with a small amount of radial clearance which allows a contact angle to be established when an axial load is applied. A small amount of inner to outer ring displacement occurs under axial loads and should therefore be considered when making a selection. Type R bearings are assembled with “Conrad” loading, which allows a 50% compliment of balls. Type R bearings can be offered with a full compliment through the use of a loading notch but precautions much be considered when axial loads are present.

Type R bearings are commonly used with two bearings on a single shaft to react off-centered radial loads resulting in a moment load through a radial load reaction or “couple”. The moment load capacity is a function of the distance between the bearing center-lines and the radial capacity of the individual bearings.

Type R bearings are also well suited for “axial float” positions when used in conjunction with a “fixed axial” position on a related axis.

Type R bearings are easily preloaded with oversized balls to reduce or eliminate radial clearance and to provide higher radial stiffness. Reduced clearance is also important for high speed applications to avoid ball skidding.

Type R bearings are offered with a 50% ball compliment and in open, single sealed, double sealed or shielded configurations. Standard bearings are offered with either a nylon or brass snap over separator.

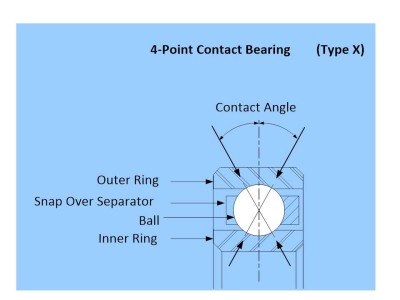

TYPE X: 4-Pt CONTACT BALL BEARING

Type X bearings are similar to a deep groove radial contact bearing with the added feature of a “Gothic Arch” ball groove design. The “Gothic Arch” geometry allows for 4-points of contact between the inner and outer race and therefore enables the bearing to resist a combination of radial, thrust and moment loading all within a single bearing.

Type X bearings are very versatile and when properly applied can greatly reduce the number of bearings, envelope, mounting concerns and cost of an assembly.

Type X bearings are subject to higher friction due to the 4-point contact and must be properly applied. They are not well suited for applications requiring both high stiffness and low, consistent torque and are not designed for use with two Type X bearings on a common shaft. Type X bearings are offered with standard radial clearances; however, they can easily be preloaded with oversized balls. Type X bearings are sensitive to the amount of preload that can be induced without adversely affecting the friction. Factors to consider are: factory set preload, interference fits between rings and mating hardware, mounting flatness, clamp ring design and applied loading.

Type X bearings are offered with a 50% ball compliment and in open, single sealed, double sealed or shielded configurations. Standard bearings are offered with either a nylon or brass snap over separator.

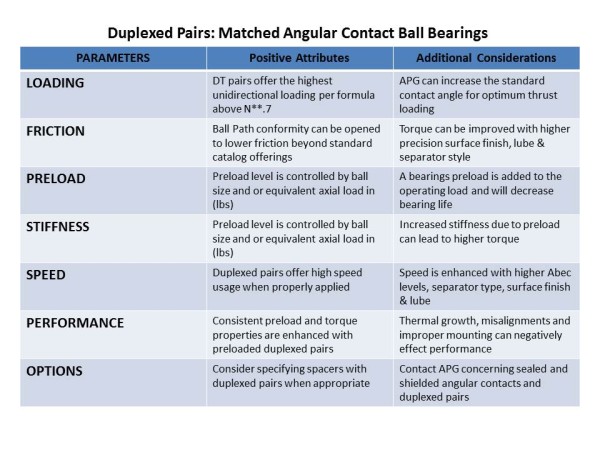

TYPE: MATCHED ANGULAR CONTACT BALL BEARINGS

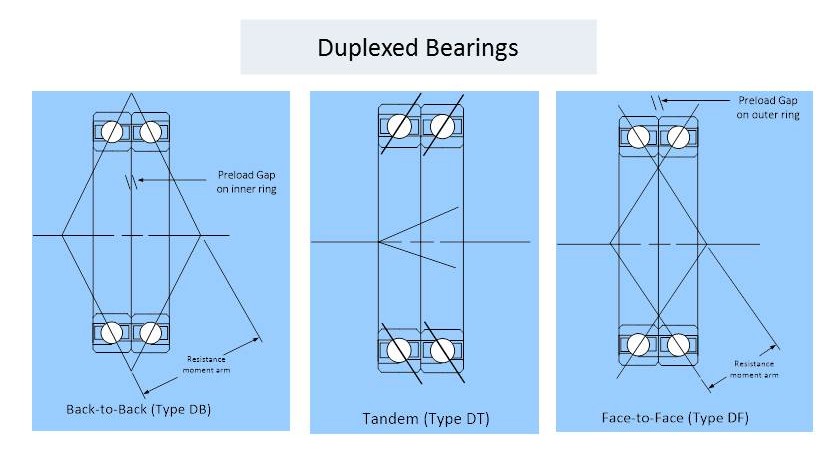

Duplexed bearings are type A bearings that are delivered as matched sets in a back-to-back, face-to-face or tandem configuration. Individual bearings within a duplexed set are closely matched for bore size, outside diameters and furnished with the appropriate race faces ground with a predetermined preload gap. The figures above show the race faces that are ground for each style of duplexed set. When the bearings are installed and axially clamped, the gap will be closed and the preload established. It should be noted that the outboard faces of duplexed sets are not normally controlled. Bearing sets should be universally ground in order to control outboard face flushness. Duplexed sets are marked with a “V” across the inside and outside diameters at the high point of radial runout.

APG will supply matched ground inner ring and outer ring spacers along with duplexed sets to meet existing envelope requirements or improve the moment capability and moment stiffness of the set. Multiple individual bearings can be provided as matched sets for applications limited in the radial direction but requiring additional capacity. Consideration should be given to load sharing effectiveness when multiple bearings are used together. The radial and thrust capacities for the set are calculated based upon multiplying the individual bearing capacities by N0.7, where N is the number of bearings in the set which are resisting the applied load. Therefore, the radial load in a typical duplexed pair is calculated by multiplying the single bearings radial capacity by (2)0.7. A tandem set with three bearings would have a thrust capacity equivalent to the single bearings thrust capacity multiplied by (3)0.7.

Back-to-back duplexed sets have a larger moment arm resistance and therefore offer greater rigidity under moment loads. The face-to-face configuration offers additional compliance in the moment direction and is more forgiving of shaft and housing misalignments.

APG offer both styles of duplexed sets with our High Performance Low Drag Outboard Seals or Shields. APG Sealed Duplexed sets can provide significant advantages in terms of achieving consistent, low torque performance with high stiffness in a tight envelope.